Introduction of oil drilling hose

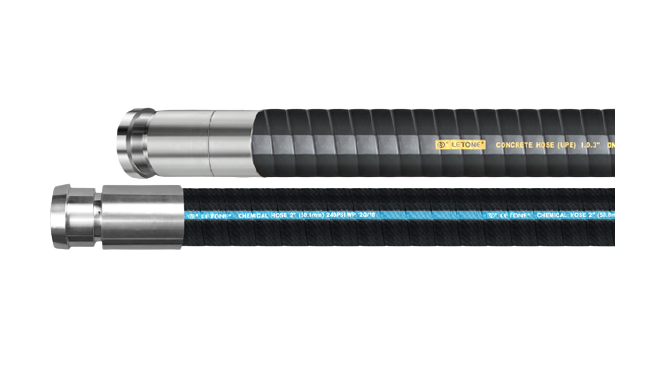

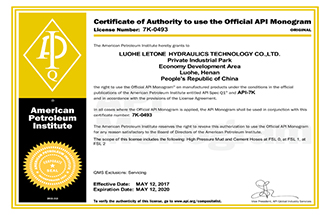

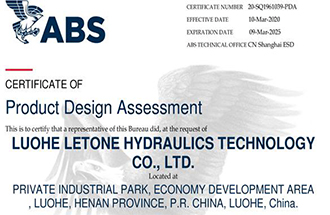

Hydraulic hoses and connectors, petrochemical and other industrial hoses and connectors, rubber compounds and rubber sealing products have become the three pillar industries of Litong. The product certifications that Litong has passed include safety standard (MA), MSHA, American Petroleum Institute (API) API-16C and API-7K, American Bureau of Shipping ABS (oil drilling equipment and steel wire braided rubber hose assembly), labor Fire certification, etc. Fully meet the needs of equipment manufacturing, oil drilling, iron and steel metallurgy, rail transit, energy, chemical and other fields.

01

high pressure

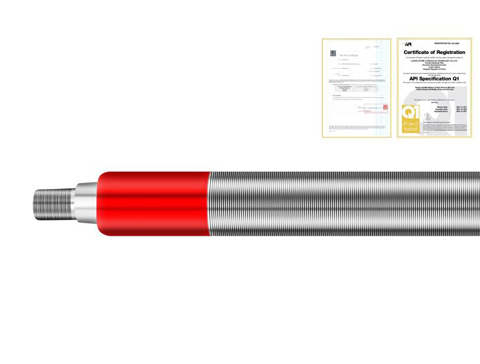

In oil drilling and exploration work, it is often necessary to bear a lot of pressure. The oil drilling and production hoses produced by us can be used normally in the environment of high pressure of 200Mpa, and can transport water-based mud and oil-based mud under high pressure. The higher the pressure, the more steel wire layers are added, and the more stringent the production process requirements are. Our designers use 2-6 layers of high-strength and super-flexible steel wire or steel wire rope, which can withstand high pressure.

02

equal diameter

After the ordinary rubber hose is installed with the joint, the inner diameter of the joint part of the hose will be compressed a lot. The oil drilling and production hose we produce has the characteristics of equal diameter. When the medium flows through the joint, the generation of eddy current is reduced, the resistance is reduced, and the protection Rubber hose, avoid friction of inner layer, longer service life.

03

Lightweight

API 7K Series - Rotary Drilling and Shock Absorbing Hose, with the characteristics of light weight, API series products are 25% lighter than other ordinary coiled pipes. Lighter hoses help improve fuel economy, reduce shipping costs, and are easier to handle and install.

Online consultation

National Service Hotline:

+86-0371-55157686